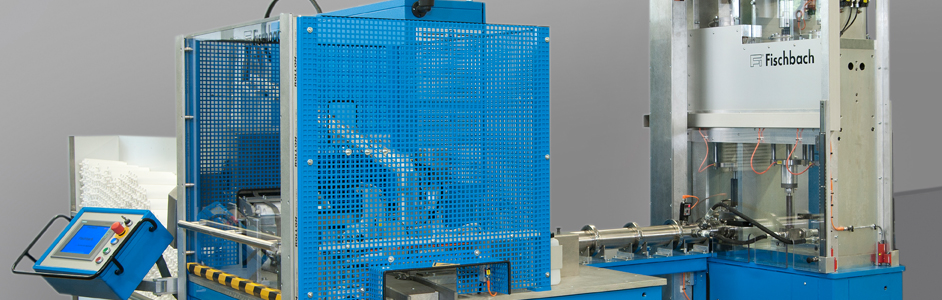

SV-1 /3K High Speed Servo Filler with integrated 3K Doser and Static Mixer

Features

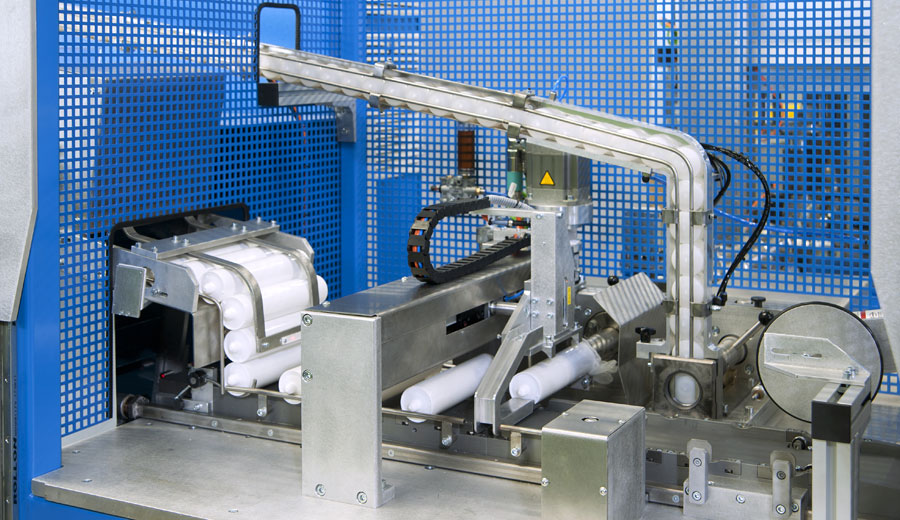

- Unit for filling, closing and marking of Cartridges similar to the type Fi-E/ED-310.

- Empty cartridges are fed from ground-level magazine, holding approx. 800 cartridges (310 ml) Fischbach E/ED-310 or similar.

- High operating speed with great precision due to the new servo-driven, easy to clean and low noise, rake conveyor.

- ntegrated, precise, servo driven and controlled high-speed dosing units, Type 'SVD+' for one main-component and two additives (pigment, extender, etc.).

- Static Mixer.

- Special designed, heavy duty structured frame for dosing systems and mixer.

- Complete system (filling machine and doser) are controlled via one Operator Interface (touch screen).

- Plunger setting station with low noise parts conveyor.

- Pulse controlled plunger lube system.

- Freely programmable control with integrated diagnostics.

- Rotation device for ink-jet printer (printer not included).

Options

- Also available in 5K or 7K configuration.

- Case Packer Fi-CH 100 and Palletizer Fi-PA, to create a fully automated, high performance line.

Technical Data

| Type of Machine: | Single Head Cartridge Filling and Closing machines SV-1 with integrated 3K Doser and Static Mixer |

|---|---|

| Output: | Up to 50 cartridges per minute at 310 ml depending on the viscosity of the material filled |

| Dosing: | Volumetric |

| Dosing Range: | 240 ml to 350 ml (base component) |

| Connecting height at Product Infeed: | 1000 mm (+/- 50 mm) |

| Voltage: | 3 x 400 V, 50 Hz or as requested |

| Control: | Siemens Simotion |

| Compressed Air: | 5 bar minimum (75 psi.) |

| Air consumption: | about 15 Nm³/h |

| Weight: | 2.3 tons |

Overview

Overview News

News Search

Search